- +86 13962947398

- sales@ytconveyor.com

- WhatsApp 7day-24h

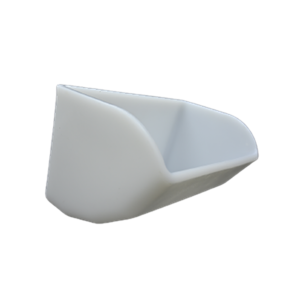

| Material | HDPE, Nylon |

|---|

DM bottomless bucket team is for agricultural use.

This bottomless bucket is installed using several bottomless buckets in a very small space with a bucket with a bottom below.

Bottom buckets can minimize the bucket installation spacing close to zero and dramatically increase the elevating capacity. Commonly the working capacity could increase by about 20%.

| Model | Bucket Dimension(mm) | Mounting Holes(mm) | Capacity(L) | |||||

|---|---|---|---|---|---|---|---|---|

| Length A |

Proj. B |

Depth C |

From Top D |

Hole Centres E |

No. of Holes |

Hole diameter |

Water Level (Z-Y) |

|

| DW0907 | 90 | 78 | 33 | 15 | 40 | 2 | 7 | 0.18 |

| DW1109A | 110 | 92 | 45 | 22 | 60 | 2 | 7 | 0.25 |

| DW1310 | 130 | 102 | 45 | 20 | 70 | 2 | 7 | 0.36 |

| DW0706 | 72 | 62 | 30 | 14 | 30 | 2 | 7 | 0.08 |

| DW1109 | 110 | 92 | 50 | 20 | 60 | 2 | 7 | 0.21 |

| DW1311 | 130 | 110 | 45 | 18 | 70 | 2 | 7 | 0.36 |

| DW1812 | 186 | 125 | 60 | 25 | 90 | 2 | 9 | 0.85 |

Installation hole size could be customized.

WhatsApp us

We will contact you within 1 working day, please pay attention to the email with the suffix “@yutungindustrial.com” or “@ytconveyor.com”.

Reach out to us today and get a free E-catalogue and our engineer's suggestion.